| Ntho | Ho qapa | Ho lahla |

| Tshebetso | Forging ke mokhoa oa ho sebelisa mochini oa forging ho etsa hore tšepe e se nang letho e hlahise deformation ea polasetiki, e le ho fumana thepa e itseng ea mochini, sebopeho le boholo. Ka forging ka felisa tšepe ascast bofokoli hlephileng tshebetso smelting, optimize microstructure, boloka ho phalla ho feletseng tšepe, kahoo thepa ea mechine ea forging ka kakaretso molemo ho feta ho lahla materail tšoanang. Boholo ba likarolo tsa bohlokoa tsa mochini tse hlokang mojaro o phahameng le boemo bo tebileng ba ho sebetsa bo sebetsa likarolo tsa forging. | Ho lahla ke mokhoa oa ho kenya tšepe ea metsi ka har'a sekoti sa ho lahla, ka mor'a ho pholile le ho tiisa ho fumana likarolo tse hlokahalang. |

| Lintho tse bonahalang | Lisebelisoa tsa forging li sebelisoa haholo tšepe e chitja, tšepe e sekoere. ho na le tšepe ea k'habone, tšepe ea alloy, tšepe e sa hloekang hammoho le tšepe e seng ferrous e sebelisoang haholo indastering ea sebaka sa marang-rang le e nepahetseng. | Hangata ho lahla ho sebelisa tšepe e bohlooho, tšepe ea dectile cast, tšepe e hahang habonolo, le "tšepe e entsoeng ka tšepe e tloaelehileng: koporo, tin bronze, wuxi bronze, aluminium alloy joalo-joalo. | Tlas'a boemo bo lekanang, forgingmetal e na le ts'ebetso e ntle ho thepa ea mochini, ha ho lahla ho phahametse ho bopa. |

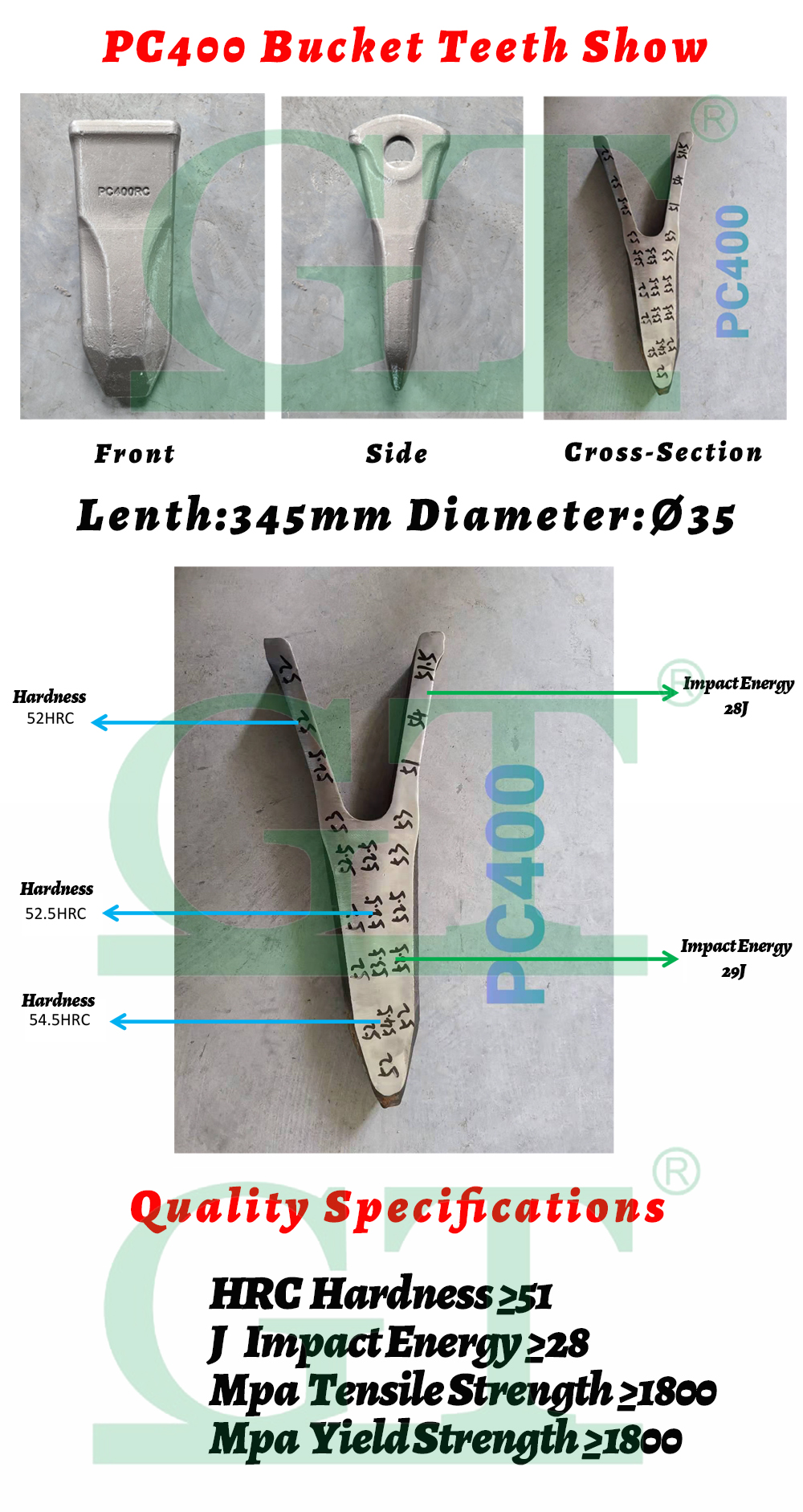

| Ponahalo | Karabelo ea oxidation ea tšepe ea ho forging nakong ea mocheso o phahameng e tla baka lijo-thollo tse nyane tsa kylin ka holim'a meno a bakete a entsoeng. Hape joalo ka ha forging e etsoa ka ho bopa, ka mor'a hore ho tlosoe sekotjana sa tumello ka hlobo, ho ne ho tla ba le mola o arohanang menong ea libakete tse entsoeng. | Ho na le mohlala oa lehlabathe le li-kiting holim'a meno a libakete. |

| Thepa ea Mechini | Ts'ebetso ea ho theha e ka tiisa tsoelo-pele ea fiber ea tšepe, 'me ea boloka tšepe e phallang ka ho feletseng, thepa e ntle ea mochine le bophelo bo bolelele ba tšebeletso ea meno a bakete, e leng mokhoa oa ho lahla o ke keng oa bapisoa. | Ha ho bapisoa le likarolo tsa ho lahla, sebopeho sa tšepe le thepa ea mochini li ka ntlafatsoa kamora ho qhekella. Mokhatlo oa ho lahla ka mor'a ho etsa deformation ea mocheso, kristale ea pele ea bulky le koro ea lijo-thollo e fetoha lijo-thollo tse ntle, le mokhatlo o tšoanang oa isometric recystallization, lumella sebopeho sa karohano ea pele ka hare ho ingot, osteoporosis, porosity slag kenyeletso le tse ling tse kopanetsoeng ho ba haufi-ufi, kahoo ho ntlafatsa polasetiki ea tšepe le thepa ea mechine.

Forging ke ho fumana sebopeho se hlokehang ka ho hatella tšepe ka deformation ea polasetiki, hangata ka hamore kapa khatello. Forging process e fana ka sebopeho se setle sa granular, mme e ntlafatsa thepa ea 'mele ea tšepe, ka ts'ebeliso e sebetsang, moralo o nepahetseng o ka netefatsa phallo ea lijo-thollo ka lehlakoreng la khatello ea maikutlo. Le hoja ho lahla ke ho fumana lintho tse entsoeng ka tšepe ka mefuta eohle ea mekhoa ea ho lahla, ke hore ho kenya tšepe ea metsi ka har'a hlobo e lokiselitsoeng ho fumana sebopeho se itseng, boholo le thepa, ka ho qhibiliha, ho lahla, ho kenya ente kapa mokhoa o mong oa ho lahla, le ho shakeout ka mor'a ho pholile, ho hloekisa le ho qetela-phekolo. |