Grouser Bar Bakeng sa Bulldozer le Excavator

Sebaka sa grouser ke karolo ea tšepe eo hangata e fumanoang mecheng e boima, joalo ka li-bulldozer le li-track loaders. E khomaretse lieta tsa pina 'me e thusa ho ntlafatsa ho ts'oara le ho tšoara ka ho loma fatše. Li-grouser bar li bohlokoa bakeng sa ho ntlafatsa ts'ebetso ea mochini libakeng tse thata, joalo ka mobu o hlephileng kapa matsoapong. Li tla ka libopeho le boholo bo fapaneng ho lumellana le lits'ebetso tse fapaneng 'me li ka nkeloa sebaka ha li tsofetse ho boloka ts'ebetso e nepahetseng.

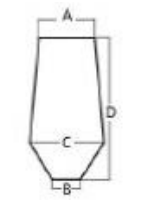

| KAROLO | A mm | B mm | C mm | D mm | Bolelele (mm) | W (kg) |

| 225 | 15 | 8 | 19 | 18 | 225 | 0.51 |

| 335 | 20 | 10 | 24 | 21 | 335 | 1.13 |

| 594 | 28.5 | 12.5 | 36.5 | 64 | 594 | 9.4 |

| 610 | 7 | 5 | 22 | 40 | 610 | 2.8 |

| 910HT-558 | 28.575 | 12.7 | 38.1 | 63.5 | 558 | 9.04 |

| 911HT-558 | 26.987 | 12.7 | 41.275 | 82.55 | 558 | 11.55 |

| 911HT-610 | 26.987 | 12.7 | 41.275 | 82.55 | 610 | 12.7 |

| ACORK3 | 10.17 | 6.35 | 19.05 | 31.75 | 76.2 | 0.28 |

| D10 | 27 | 14 | 36 | 68 | 610 | 10 |

| D10-558 | 28.58 | 14.29 | 38.1 | 66.675 | 558 | 9.5 |

| D10-610 | 28.58 | 14.29 | 38.1 | 66.675 | 610 | 10.4 |

| D11 | 27 | 14 | 41 | 82.5 | 711 | 15.2 |

| D12-610 | 34.925 | 12.7 | 44.45 | 76.2 | 610 | 13.8 |

| D7-508 | 16 | 7.94 | 19 | 35.5 | 508 | 2.5 |

| D8-508 | 19.05 | 9.525 | 25.4 | 50.8 | 508 | 4.4 |

| D9-558 | 24.1 | 7.94 | 33 | 50.8 | 558 | 6.1 |

| D9-610 | 24.1 | 7.94 | 33 | 50.8 | 610 | 6.6 |

| ECORK4 | 10.17 | 7.52 | 19.41 | 38.2 | 76.2 | 0.34 |

| KCORK-4.25" | 14.3 | 9.5 | 19.1 | 31.75 | 108 | 0.44 |

| SCORK-4.25" | 25.4 | 7.9 | 28.6 | 50.8 | 108 | 1.1 |

| TCORK-4.25" | 25.4 | 6.4 | 28.6 | 38.1 | 108 | 0.84 |

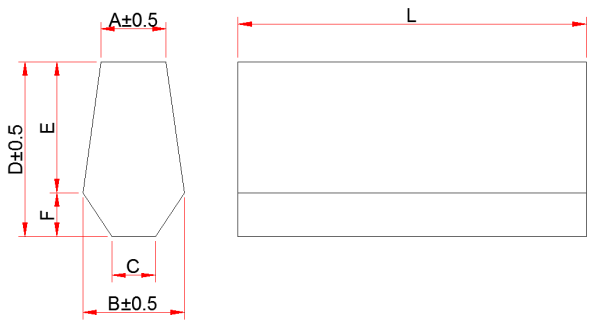

Lintho tse fapaneng bakeng sa litšupiso

lintho tse bonahalang: 65Mn Thata: HB300~HB320 Bolelele bo ka khonehang, max 6000mm

| Nomoro ea karolo | A | B | C | D | E | F | L | W (KG) |

| BAR-C-3 | 14.3 | 22.2 | 9.53 | 38.11 | 28.58 | 9.53 | 76.2 | 0.405 |

| BAR-K-4 | 14.3 | 19.1 | 9.53 | 31.76 | 34.93 | 9.53 | 101.6 | 0.4075 |

| BAR-L-3 | 11.1 | 15.9 | 6.35 | 25.4 | 19.05 | 6.35 | 76.2 | 0.1974 |

| BAR-E-3 | 9.5 | 19.1 | 7.94 | 38.1 | 31.75 | 6.35 | 76.2 | 0.325 |

| BAR-A-3 | 9.5 | 15.9 | 6.35 | 34.93 | 28.58 | 6.35 | 76.2 | 0.261 |

Material : 40Cr Hardness : HB500 Casting le Heat kalafo e hlokahalang.

| Nomoro ea karolo | A | B | C | D | E | F | L | W (KG) |

| ECORK 3 | 9.5 | 19.1 | 7.94 | 38.15 | 31.8 | 6.35 | 76.2 | 0.326 |

| GCORK 4 | 14.3 | 25.4 | 9.53 | 44.46 | 34.93 | 9.53 | 101.6 | 0.69 |

| JCORK 4 | 19.1 | 28.6 | 9.53 | 60.3 | 49.2 | 11.1 | 101.6 | 1.11 |

| ACORK 3 | 9.5 | 15.9 | 6.35 | 31.7 | 25.4 | 6.35 | 76.2 | 0.237 |

| WCORK 2.5 | 8 | 14.3 | 6.5 | 19.1 | 13.92 | 5.18 | 63.5 | 0.105 |

| KCORK 4 | 14.3 | 19.1 | 9.53 | 31.76 | 22.23 | 9.53 | 101.6 | 0.405 |

| HCORK 4 | 15.9 | 25.4 | 9.53 | 52.39 | 41.28 | 11.11 | 101.6 | 0.835 |

| CCOR 3 | 14.3 | 22.2 | 9.52 | 38.1 | 28.58 | 9.52 | 76.2 | 0.405 |

Boitsebiso : 42CrMoNi Hardness : HB500-550 Kalafo ea ho lahla le Mocheso e hlokahalang.

| Nomoro ea karolo | A | B | C | D | E | F | L | W (KG) |

| D9-610 | 24.1 | 33 | 7.94 | 50.8 | 41.28 | 9.53 | 610 | 6.6 |

| D10-610 | 28.58 | 38.1 | 14.29 | 66.68 | 57.15 | 9.53 | 610 | 10.4 |

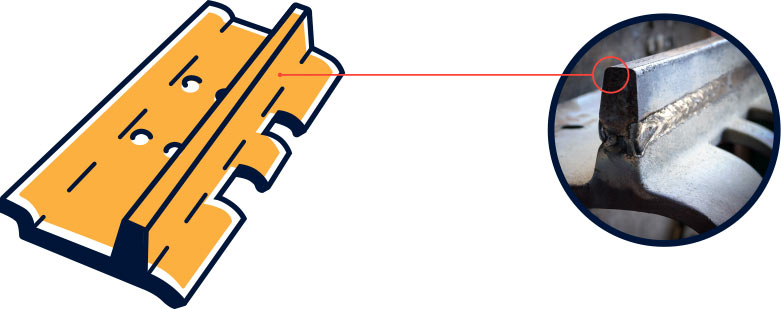

- KE SHEPE EFE E THUSANG MORAO OA HAO OA RARE?

TS'ELISITSOE SEBAKA

- Mokhoa oa ho apara o ntse o le hohle

- Seeta se khaotsoe bakeng sa sebaka se bataletseng

- E sebetsa hantle le li-welders tse ikemetseng

RETS'ELISITSOE BABA

- Mokhoa oa ho roala o chitja o nang le mapheo a tsofetseng haholo

- E felisa tlhoko ea ho kuta

- Lipheletso tsa bar li koetsoe ka angle ea 45 degree bakeng sa khanyetso e fokolang le tšehetso e eketsehileng

- Hooked bar ends e etselitsoe ho lekana lieta tsa pina ka ho roala ho matla metseng

- E loketse bakeng sa lieta tsa pina tse cheselitsoeng tšimong

TS'ELISITSOE MOKHOA

- Mokhoa oa ho apara o chitja hanyenyane

- E felisa tlhoko ea ho kuta

- Sebopeho sa bar se kobehileng se fokotsa palo ea ho tlatsa weld e hlokahalang

- E loketse bakeng sa lieta tsa pina tse cheselitsoeng tšimong

TŠEBELETSO BOR

- Mokhoa oa ho apara o ntse o le hohle

- Seeta se khaotsoe bakeng sa sebaka se bataletseng

- Lipheletso tsa bar li koetsoe ka angle ea 45 degree bakeng sa khanyetso e fokolang le tšehetso e eketsehileng

- E sebetsa hantle le li-welders tse ikemetseng